QC&QA

To make sure that our pumping units provided to you perfectly satisfy your requirements, we have established a systemic and strict quality control mechanism. We could provide products that have been certified to the CE mark, ISO9001 standards or other industrial standards. Meanwhile, we could provide quality control record and related report to you if necessary, such as "physical and chemical property report of materials for pump’s main parts", "rotor balancing report", "hydrostatic test report" and "pre delivery inspection report". All in all, we take every link of the quality control serious, assuring that each pumping unit to enjoy good quality and reliable performance.

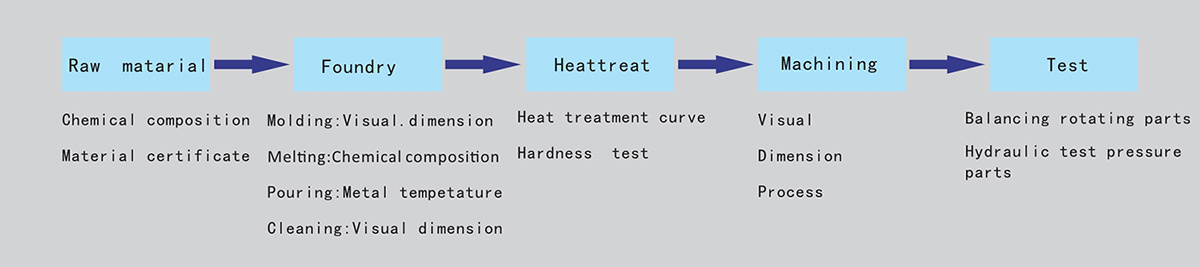

Components: QC key point

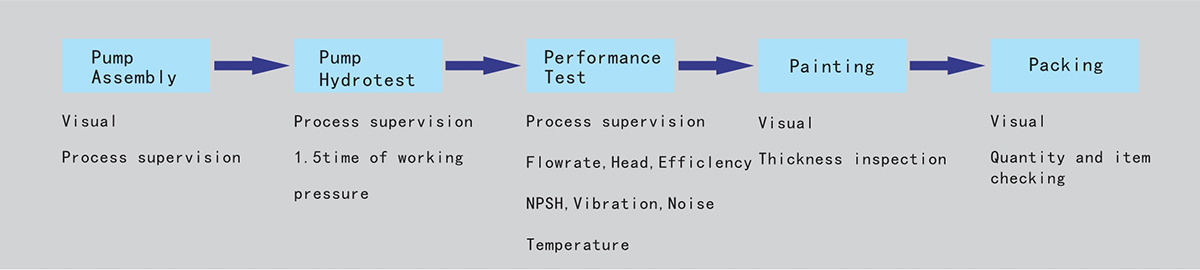

Pumps: QC key point

Raw material inspection:

--Sub-supplies are assessed and approved.

All the incoming materials are with certificate or are tested in lab.

Casting Inspection:

Melting

chemical composition by spectrometer, fill in composition sheet and reserve sample

of each furnace for 6 month.

Molding: Each step of molding is checked by and documented by inspector.

Pouring: Check metal temperature before pouring and after pouring.

Cleaning

check dimension before painting.

Machining Inspection:

Self Check and Mutual Check

First piece Check

Procedure Check

Entering Warehousing Check

Assembly Inspection and Test

Inspectors monitor the whole assembly procedure

Hydraulic test: 1.5time of working pressure