NF(R) froth pump

NF Series of Froth Pumps is a new type,high efficiency &. energy saving pump product which is manufactured only by our works under the advance manufacture technology introduced from Warman International Ltd. in Australia. These froth pumps are suitable for handing solids-liquid mixture, special for deliver ing frothy pulp generated in flotation machines in matallferous and coal flotation circuits.

key word:

froth pump、gravel pump

Category:

Froth pump

Vertical Slurry Pumps

NF(R) froth pump

NF Series of Froth Pumps is a new type,high efficiency &. energy saving pump product which is manufactured only by our works under the advance manufacture technology introduced from Warman international Ltd. in Australia. These froth pumps are suitable for handing solids-liquid mixture, special for deliver ing frothy pulp generated in flotation machines in matallferous and coal flotation circuits.

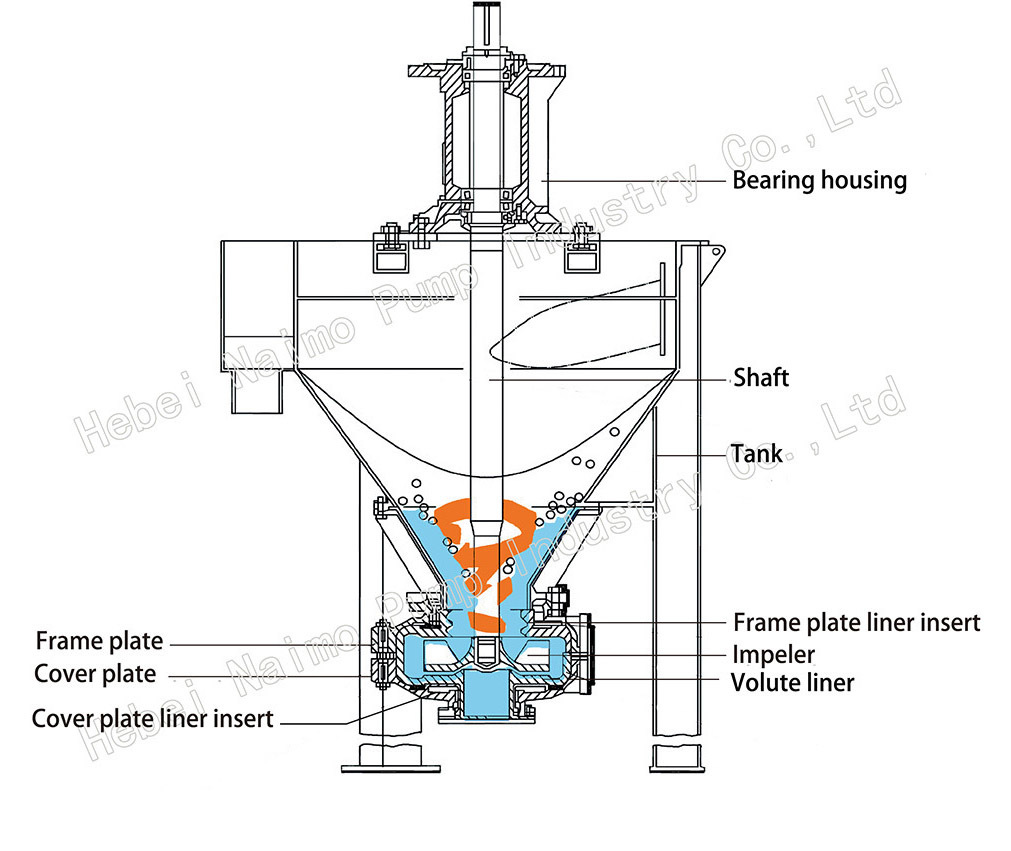

The basic principle of the pump operation is to de-aerate or partially de-aerate the froth before it enters the pumping. Its handing capacity of the pump is much higher than that of other types of slurry pump without shaft seal and sealing water. The froth pump is a perfect pump for handing frothy pump indeed.

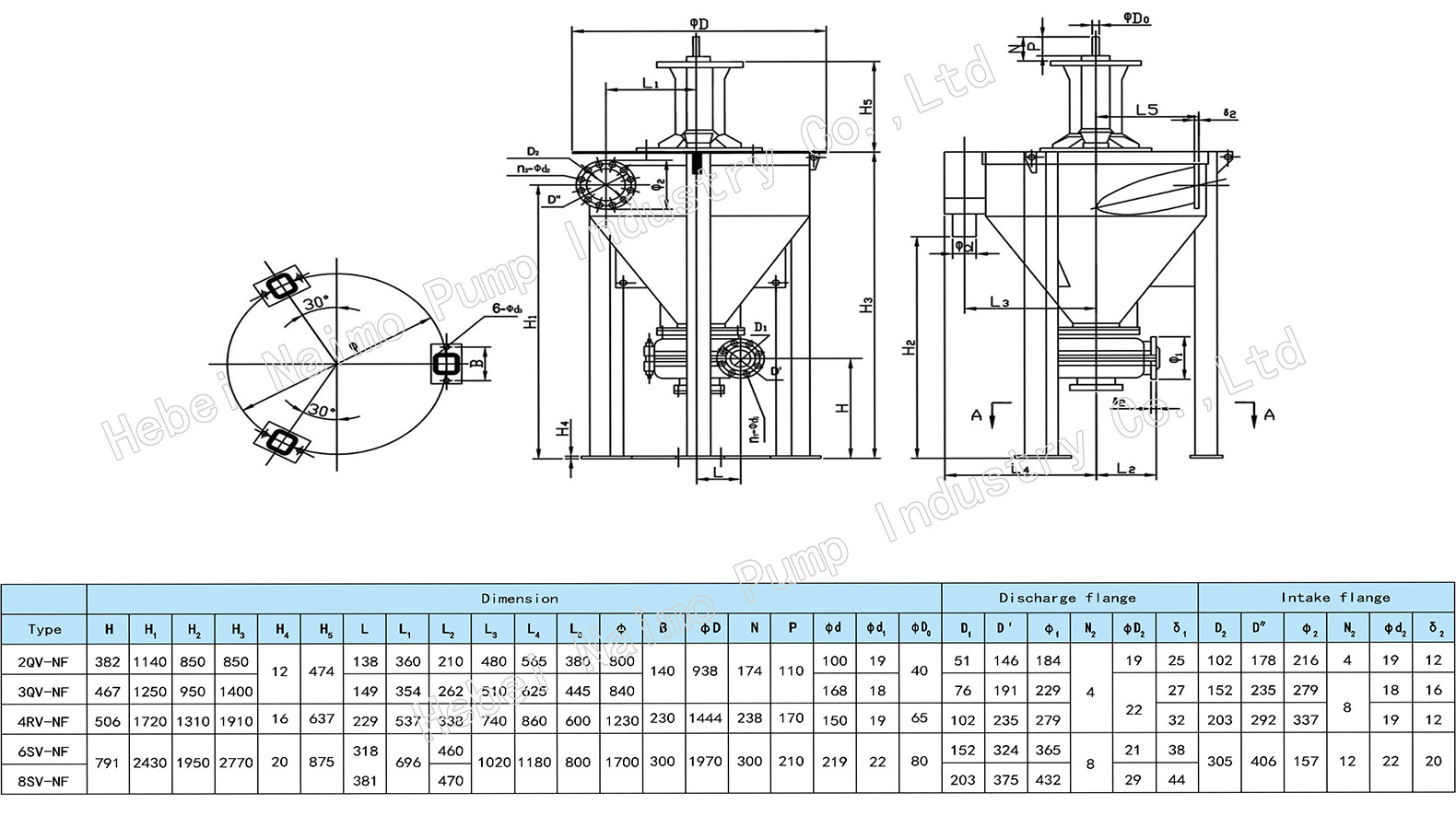

The construction of pump head is double casings which is similar with standard construction of Warman slurry pump.All wet-parts can be supplied in Ni-hard, high chrome alloy iron and pressure-moulded natural or synthetic rubber. The driver end can be exchanged with that of type SP &. SPR pumps. The per-tank is fabr icated with steel plate. Its inner wall of the tank can be covered eith liner according to different medium pumped. The discharge branch can be positioned at intervals of 45 degrees by request and or iented to any eight positions to suit installations and applications. The advantages of the pump are of excellent performance, easy assembly &. disassembly,high reliability and etc.

Material Options

|

Code |

Material # |

Hardness |

Performance |

Application |

|

A01 |

KmTBCr8 |

≥55 |

Abrasion-resistant performance is about 10% less than A05 |

Mud & slag application |

|

A03 |

KmTBNi4Cr2 |

≥56 |

Abrasion-resistant performance is about 20% less than A05 |

Neutral water-sand slurry and applications with lower impact load |

|

A05 |

KmTBCr26 |

≥56 |

Ranks second only to A07 in abrasion-resistant performance; fair corrosion-resistant performance. |

High impact load abrasion condition; PH rate ranging from 5 to 12 |

|

A07 |

KmTBCr15Mo3 |

≥59 |

Best abrasion-resistant performance; corrosion-resistant performance is inferior to A05 |

High impact load abrasion condition |

|

A11 |

KmTBCrMnMo3 |

38-42 |

Mild corrosion-resistant; lower hardness; drilling and tapping operations are applicable. |

Fine particles with light abrasion. |

|

A33 |

|

≥35 |

Abrasion-resistant performance is close to A03; fair corrosion-resistant performance |

Oxide slurry with PH rate no less than 1, like phosphor-gypsum in phosphate fertilizer plant, nitric acid, sulph-oacid and phosphoric acid, etc. |

|

A49 |

|

≥43 |

Fair abrasion-resistant performance, close to A03; fair corrosion-resistant performance in media with lower PH rate. |

Corrosion conditions with low PH rate, especially for flue gas and FGD devices for media of PH≥4; general suitable for lower acid condition. |

|

A12 |

|

≥62 |

Higher abrasion-resistant performance than A05; fair corrosion-resistant performance; suitable for media with PH rate is 6-16, where A05 is not suitable. |

High abrasive slurry with fine particles. |

|

A61 |

|

63-68 |

Optimized abrasion-resistant performance than A12 |

High abrasive slurry with fine particles. |

|

Material |

Material # |

Applications |

|

Natural Rubber |

R08 |

R08 is low to medium hardness rubber used for impellers where slurry contains fine particles and erosive. |

|

Natural Rubber(soft) |

R26 |

R26 is soft natural rubber used for liners where slurry contains fine particle and more erosive. |

|

Natural Rubber(soft) |

R33 |

R33 is widely used for frame plate liners, cover plate liners and impellers. Maximal particle diameter is 10mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 75℃. |

|

Natural Rubber |

R55 |

R55 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 20mm, impeller peripheral speed should be less than 27.5m/s; suitable for temperature not exceeding 75℃. |

|

EPDM Rubber |

S01 |

S01 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 8mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 120℃(continuous duty) or 140℃(discontinuous duty). |

|

Nitrile Rubber(NBR) |

S12 |

S12 is widely used for frame plate liners, cover plate liners, throat bushes, lip seals, impellers and expellers. Maximal particle diameter is 7mm; impeller peripheral speed should be less than 27m/s; suitable for temperature not exceeding 95℃. |

|

Butyl Rubber |

S21 |

S21 is widely used for impellers, frame plate liners, cover plate liners, expellers, volute seals and throat bushes,. Maximal particle diameter can be 7mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 100℃. |

|

Hypalon |

S31 |

S31 can be used for impellers, frame plate liners, cover plate liners and throat bushes,. It is recommended to use for strong acid slurry with mild or moderate corrosion. Maximal particle diameter can be 10mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 110℃. |

Consult NAIMO Pump Industry for unlisted materials.

PREV

NEXT

PREV

无

NEXT

RELATED PRODUCTS

PRODUCT MESSAGE