WN Dredging Pump

WN dredge pump is a new type of sludge pump researched & manufactured by our company basing on International (Warman ) Gravel Pumps, aiming at rivers and seas out of repair. NM pump is a single-stage single suction cantilever horizontal centrifugal pump with advantages of light weight, good wear-resistant, super dredging performance, perfectly suited for the dredge on the whole construction,high multiple economy benefits, etc.. It throughout meets requirements of the dredge to dredging pumps.

key word:

froth pump、gravel pump

Category:

Horizontal slurry pump

Sand gravel & dredge pump

WN Dredging Pump

2.1 Production Overview

WN dredge pump is a new type of sludge pump researched & manufactured by our company basing on International (Warman ) Gravel Pumps, aiming at rivers and seas out of repair. NM pump is a single-stage single suction cantilever horizontal centrifugal pump with advantages of light weight, good wear-resistant, super dredging performance, perfectly suited for the dredge on the whole construction,high multiple economy benefits, etc.. It throughout meets requirements of the dredge to dredging pumps.

2.2 Main Features

2.2.1 Structure suitable for dredging ship:

The structure of 200WN-500WN type pumps are single-casing, single-stage, single-suction, cantilever and horizontal. According to the connection with the pump head, two structures can be offered:self-carrying bracket and pump-box assembly/pump integrated with gearbox. The lubrication for thebracket is grease or thin oil.

The structure of600WN-1000WN type pumps are double-casing, single-stage, single suction, cantilever and horizontal. It has self-carrying bracket. Lubrication is forced thin oil lubricating. The double-casing

design can ensure the liner can work till it is worn out, and if the liner crack, water can not enter into the pump.

2.2.2 Easy to Disassembly and Installation, Convenient Maintenance:

WN type pump adopts front-disassembly structure in favor of easy disassembly and maintenance. Also it is equipped with special disassembly tools for each different part according to each part's features.

The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.

2.2.3 Good Perfomance on NPSH:

The good NPSH performance of WN type pump ensures the strong suction ability as well as deeperdredging depth and denser dredging concentration.

2.2 4 Good Wear-resistant Performance, Long Service Time of Wet Parts:

Wet parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher

resistance wear and resistance abrasion features. The hardness of our material that is researched and tested successully by us can research 70HRC.

2.2.5 Reliable Shaft Sealing Without Leakage:

The shaft of 200WN-500WN dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing.

The shaft of 600WN-1000WN dredging pump adopts spiral sleeve L (shape) rubber sealing device that consists of three L sealing ring and one special thread shaft sleeve.

2.3 Advantages

2.3.1 Advanced hydraulic model, CAD 3D design, high eficiency and obvious energy-saving

2.3.2 Large dredging depth, high density of dredging mud, good NPSH and strong suction lift ability

2.3.3 Strong through-put. The pump can persistently discharge gravel, high plastic soil lump, etc.

2.3.4 The pump can be directly matched with either motor or diesel engine

2.3.5Wide application. It can be used in various kinds of soil quality. Generally, the pump is matched with an impeller with 3 or 5 pieces of vane. At the same time, the impellers can be provided with various

diameters and vane types to suit kinds of working condition.

2.3.6 Little hydraulic loss, high efficiency and low oil- consumption

2.3.7 Little volume, light weight

2.3.8 Steady operating, itte vibration, low noise

2.3.9 Simple & reliable construction, easily disassembly & assembly, convenient maintaince

2.3. 10 Reliable sealing without leakage

2.3.11 Long operating life of parts

2.3.12 Long operating life of parts

2.4Type Meaning

Ex:450WN

450: Pump exports in diameter(mm)

WN: Dredging pump

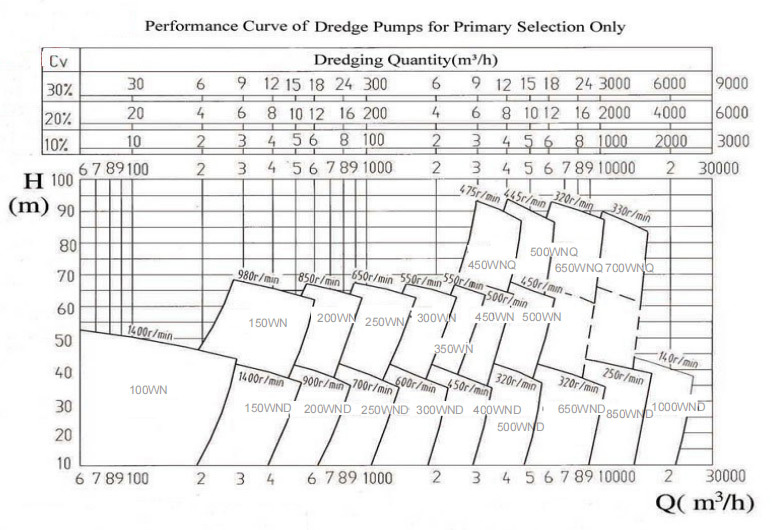

2.5 Selection chart

2.6 Performance Table

Material Options

|

Code |

Material # |

Hardness |

Performance |

Application |

|

A01 |

KmTBCr8 |

≥55 |

Abrasion-resistant performance is about 10% less than A05 |

Mud & slag application |

|

A03 |

KmTBNi4Cr2 |

≥56 |

Abrasion-resistant performance is about 20% less than A05 |

Neutral water-sand slurry and applications with lower impact load |

|

A05 |

KmTBCr26 |

≥56 |

Ranks second only to A07 in abrasion-resistant performance; fair corrosion-resistant performance. |

High impact load abrasion condition; PH rate ranging from 5 to 12 |

|

A07 |

KmTBCr15Mo3 |

≥59 |

Best abrasion-resistant performance; corrosion-resistant performance is inferior to A05 |

High impact load abrasion condition |

|

A11 |

KmTBCrMnMo3 |

38-42 |

Mild corrosion-resistant; lower hardness; drilling and tapping operations are applicable. |

Fine particles with light abrasion. |

|

A33 |

|

≥35 |

Abrasion-resistant performance is close to A03; fair corrosion-resistant performance |

Oxide slurry with PH rate no less than 1, like phosphor-gypsum in phosphate fertilizer plant, nitric acid, sulph-oacid and phosphoric acid, etc. |

|

A49 |

|

≥43 |

Fair abrasion-resistant performance, close to A03; fair corrosion-resistant performance in media with lower PH rate. |

Corrosion conditions with low PH rate, especially for flue gas and FGD devices for media of PH≥4; general suitable for lower acid condition. |

|

A12 |

|

≥62 |

Higher abrasion-resistant performance than A05; fair corrosion-resistant performance; suitable for media with PH rate is 6-16, where A05 is not suitable. |

High abrasive slurry with fine particles. |

|

A61 |

|

63-68 |

Optimized abrasion-resistant performance than A12 |

High abrasive slurry with fine particles. |

|

Material |

Material # |

Applications |

|

Natural Rubber |

R08 |

R08 is low to medium hardness rubber used for impellers where slurry contains fine particles and erosive. |

|

Natural Rubber(soft) |

R26 |

R26 is soft natural rubber used for liners where slurry contains fine particle and more erosive. |

|

Natural Rubber(soft) |

R33 |

R33 is widely used for frame plate liners, cover plate liners and impellers. Maximal particle diameter is 10mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 75℃. |

|

Natural Rubber |

R55 |

R55 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 20mm, impeller peripheral speed should be less than 27.5m/s; suitable for temperature not exceeding 75℃. |

|

EPDM Rubber |

S01 |

S01 is widely used for impellers, frame plate liners, cover plate liners and throat bushes. Maximal particle diameter can be 8mm; impeller peripheral speed should be less than 25m/s; suitable for temperature not exceeding 120℃(continuous duty) or 140℃(discontinuous duty). |

|

Nitrile Rubber(NBR) |

S12 |

S12 is widely used for frame plate liners, cover plate liners, throat bushes, lip seals, impellers and expellers. Maximal particle diameter is 7mm; impeller peripheral speed should be less than 27m/s; suitable for temperature not exceeding 95℃. |

|

Butyl Rubber |

S21 |

S21 is widely used for impellers, frame plate liners, cover plate liners, expellers, volute seals and throat bushes,. Maximal particle diameter can be 7mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 100℃. |

|

Hypalon |

S31 |

S31 can be used for impellers, frame plate liners, cover plate liners and throat bushes,. It is recommended to use for strong acid slurry with mild or moderate corrosion. Maximal particle diameter can be 10mm; impeller peripheral speed should be less than 30m/s; suitable for temperature not exceeding 110℃. |

Consult NAIMO Pump Industry for unlisted materials.

NEXT

PREV

无

NEXT

RELATED PRODUCTS

PRODUCT MESSAGE